Waterproof Flooring Options for Commercial Spaces: The Complete Guide

Commercial spaces face water exposure from spills, cleaning and humidity, which damages traditional flooring and disrupts business. Over the past decade, modern waterproof flooring technology has evolved, with improved core materials such as plastic composites now providing durable commercial flooring and genuine waterproof performance in high-traffic commercial settings.

Quality waterproof flooring is an investment and protects your business operations while reducing maintenance costs. Understanding the distinction between waterproof and water-resistant products helps you make informed decisions. In the DFW Metroplex, humidity fluctuations and slab moisture require flooring that won’t buckle, mold, or slip. At All American Flooring, business owners in Dallas-Fort Worth can choose from five proven waterproof solutions designed for different commercial applications and budgets.

Understanding Waterproof vs. Water-Resistant Flooring

True waterproof flooring withstands standing water for 24 hours or more without damage to the core material. The construction includes waterproof cores made from stone plastic composite, wood plastic composite or vinyl that pass 24-hour submersion tests and edge-swell evaluations.

The spectrum of water resistance includes these distinct performance categories:

- Moisture-resistant: This flooring type handles humidity effectively but fails under standing water conditions.

- Water-resistant: Flooring in this category provides temporary surface protection only, with no core protection from prolonged exposure.

- Waterproof: Flooring that is truly waterproof offers complete protection of the core material, edges and seams.

Many manufacturers market flooring as waterproof when only the surface resists water. Proper installation and sealing are critical, as improper methods compromise performance. Buyers should verify compliance with American National Standards Institute (ANSI) standards and get third-party certification, such as an installer’s warranty.

Top Waterproof Commercial Flooring Solutions

Determining the best waterproof flooring for commercial use requires evaluating your environment, traffic and budget. Each of these five options offers distinct application advantages.

1. Luxury Vinyl Tile (LVT) and Luxury Vinyl Plank (LVP)

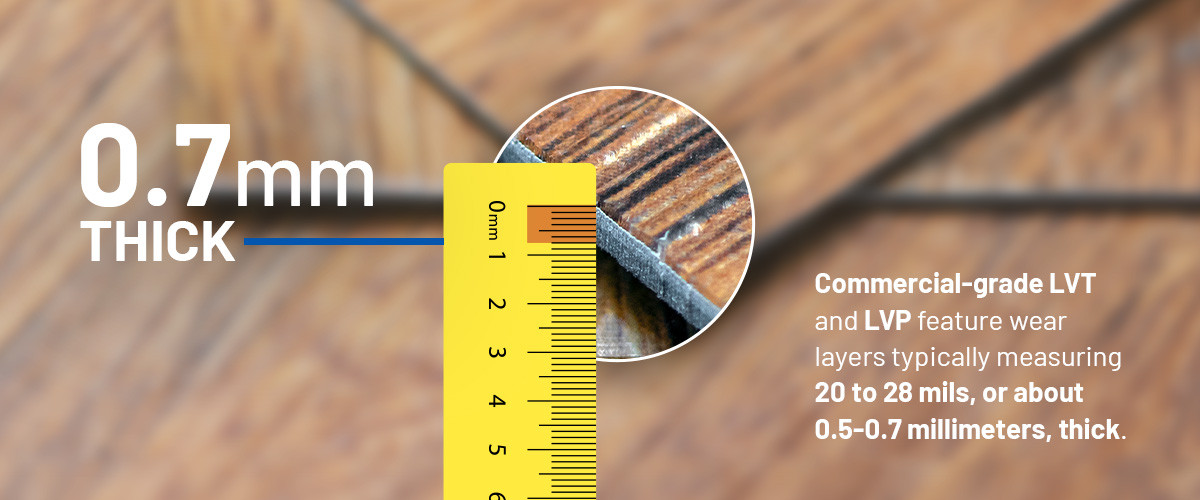

Commercial-grade LVT and LVP feature wear layers typically measuring 20 to 28 mils, or about 0.5-0.7 millimeters, thick. Rigid-core construction with stone-plastic composite supports heavy equipment without denting. These products excel in multiple commercial applications, including:

- Offices: LVT and LVP work well in offices as they’re quiet underfoot, with a professional appearance and low maintenance requirements.

- Retail spaces: These flooring types withstand shopping cart traffic and frequent cleaning protocols.

- Healthcare facilities: Luxury vinyl lends itself well to easy disinfection, with a seamless appearance and support for infection control.

- Restaurant front-of-house: The attractive design of this flooring meets the durability needs for front-of-house work.

Installation methods vary based on commercial requirements:

- Glue-down installation: This type of installation is a permanent solution for rolling loads and heavy equipment movement.

- Click-lock floating: Laying down click-lock flooring means faster installation with easier individual plank replacement.

- Loose-lay application: This method requires minimal adhesive for temporary spaces or flexible configurations.

Design versatility offers wood-look planks and stone-look tiles. Midrange options generally have 5-20 year lifespans and low maintenance requirements.

2. Sheet Vinyl and Vinyl Composition Tile

Large sheet vinyl rolls minimize seams, and heat-welded seams create waterproof barriers superior to grout. Seamless surfaces benefit healthcare by meeting infection control standards and preventing bacterial growth. Chemical resistance properties make these materials ideal for demanding environments such as labs because they protect against:

- Bleach and disinfectants: Vinyl as a material withstands hospital-grade chemicals without degradation or discoloration.

- Oils and greases: This flooring resists food service spills and commercial kitchen conditions.

- Cleaning protocols: Vinyl will maintain its appearance with rigorous daily sanitation requirements.

- Equipment compatibility: Sheet and tile vinyl works well with equipment such as commercial auto-scrubbers.

Vinyl flooring is ideal for large areas and has a lower up front cost than all the other options.

3. Waterproof Porcelain and Ceramic Tile

Porcelain absorbs less than 0.5% water by weight, while ceramic offers slightly higher but still excellent water resistance. Commercial applications include:

- Restaurant kitchens and dining areas: These tiles handle spills and heavy foot traffic patterns extremely well.

- Building entryways: Porcelain and ceramic tiles withstand weather exposure and moisture tracking from outdoors.

- Commercial bathrooms: The water absorption of this tile flooring is ideal for high-moisture environments with frequent cleaning.

Slip resistance ratings from ANSI require a minimum dynamic coefficient of friction of 0.42 for safety. Making your floor accessible requires a textured surface under the Americans with Disabilities Act (ADA).

Nearly unlimited color and pattern options allow brand integration and cohesive design. Tile requires minimal maintenance, but grout lines need regular sealing. Epoxy grout offers superior water resistance over standard cement grout.

4. Commercial Epoxy Flooring

Well-installed epoxy flooring creates waterproof surfaces with no joints or seams. This nonporous material prevents water penetration in industrial and high-moisture environments while delivering exceptional chemical resistance against:

- Oils and greases: Epoxy resists petroleum-based products without surface staining or degradation.

- Solvents and chemicals: As it is nonporous, it is suited for harsh industrial conditions and manufacturing spaces that use chemicals.

- Acids: Epoxy flooring handles acidic materials without compromising surface integrity or appearance.

- Long-term exposure: This flooring will maintain performance despite prolonged chemical contact.

Installation requires proper surface preparation, moisture testing and ventilation. Curing generally takes 24-72 hours for light traffic and seven days for a complete cure, which may require phased installation or temporary closure. Epoxy provides 10-20 years of protection with minimal maintenance and occasional recoating.

5. Rubber Flooring

Naturally water-resistant rubber handles moisture from cleaning and spills while providing quick-drying surfaces that prevent slip hazards. Best applications include:

- Fitness centers: Rubber cushioning reduces impact, while extreme durability handles equipment.

- Healthcare facilities: This type of flooring is comfortable for staff to stand on during extended shifts.

- High-traffic corridors: Rubber offers excellent sound absorption, reducing noise in multistory buildings.

- Entryways: The slip-resistant nature of this flooring surface protects high-traffic areas.

Textured surfaces offer excellent wet traction, and cushioning reduces fall risk. Regular sweeping and damp mopping maintain appearance, but avoid harsh solvents.

Industry-Specific Waterproof Flooring Needs

Different industries have varied flooring needs for safety and compliance.

Restaurants and Food Service

Restaurants need durable, nonporous, slip-resistant flooring for safety and bacterial prevention. It must withstand heavy equipment, traffic, thermal shock and chemical exposure for ANSI compliance.

Healthcare and Medical Facilities

Healthcare facilities require seamless, chemical-resistant surfaces for bacteria prevention and to withstand rigorous cleaning and disinfectants. Comfortable flooring reduces staff fatigue.

Retail and Office Spaces

Retail and office spaces balance aesthetics with durability, reinforcing brand identity and improving productivity via noise reduction. Daily spot cleaning and regular deep cleaning are essential.

Industrial and Warehouse Environments

Industrial environments using forklifts or pallet jacks require gouge and impact resistance. Chemical exposure from oils or solvents demands nonreactive, slip-resistant and static-controlled surfaces.

Installation and Maintenance Considerations

Subfloor preparation includes ASTM moisture testing for relative humidity or calcium chloride, mitigating these issues with epoxy sealers and moisture barriers to ensure a dry surface. Concrete requires adequate curing, level surfaces and the removal of contaminants.

Documentation proving proper installation and maintenance protects warranty coverage. Daily maintenance protocols vary by flooring type:

- LVT or LVP: For best results, sweep or vacuum daily, and damp mop with a pH-neutral cleaner as needed.

- Sheet vinyl: To keep vinyl clean, use auto-scrubbers with manufacturer-approved cleaning products.

- Tile: Mop porcelain or ceramic tiles regularly, periodically clean the grout and have them professionally sealed.

- Epoxy: You only need to sweep debris regularly and apply occasional pressure washing for deep cleaning.

- Rubber: Ensure your rubber floors remain clean by sweeping daily, damp-mopping with water-based cleaners and avoiding petroleum-based products.

Replace floors when excessive wear affects the appearance, water damage compromises the integrity or repair costs approach replacement costs.

Finding the Right Balance for Your Business

Evaluating waterproof flooring means considering the total lifetime value over installation costs. A higher up-front investment in quality flooring and professional installers generally means fewer replacements and lower long-term costs due to durability.

Maintenance expenses vary by material:

- Tile: Maintenance expenses include minimal daily care with periodic grout sealing.

- LVT or LVP: You’ll eliminate refinishing costs with this material.

- Epoxy: This durable flooring requires extremely low maintenance over the decades.

- Vinyl: You’ll need to regularly strip and wax vinyl, which increases labor costs.

Commercial flooring investments may qualify for depreciation deductions and Section 179 deductions.

Partner With All American Flooring for Your Commercial Waterproof Flooring Project

Choosing waterproof flooring for your business means understanding true waterproof performance vs. water-resistant treatments and recognizing longevity benefits over initial price. All American Flooring brings over 35 years of trusted Dallas-Fort Worth experience, so we can help you find the right flooring for your industry needs, from healthcare infection control to restaurant grease resistance.

Our team offers commercial-grade waterproof solutions, and every installation includes our 110% unbeatable price guarantee. We provide flooring and installation that meet ANSI standards, reducing long-term maintenance, replacements and business disruptions.

Our commercial warranty covers installation for three years and the manufacturer’s product warranties.

Our Commercial Service Area:

- Dallas: Downtown, Uptown, Design District, and surrounding areas.

- Fort Worth: Stockyards, Cultural District, and Clearfork.

- Suburbs: Plano, Frisco, Irving, Arlington, Mckinney, Richardson, Allen and Grand Prairie.

Contact All American Flooring today to schedule a free consultation.